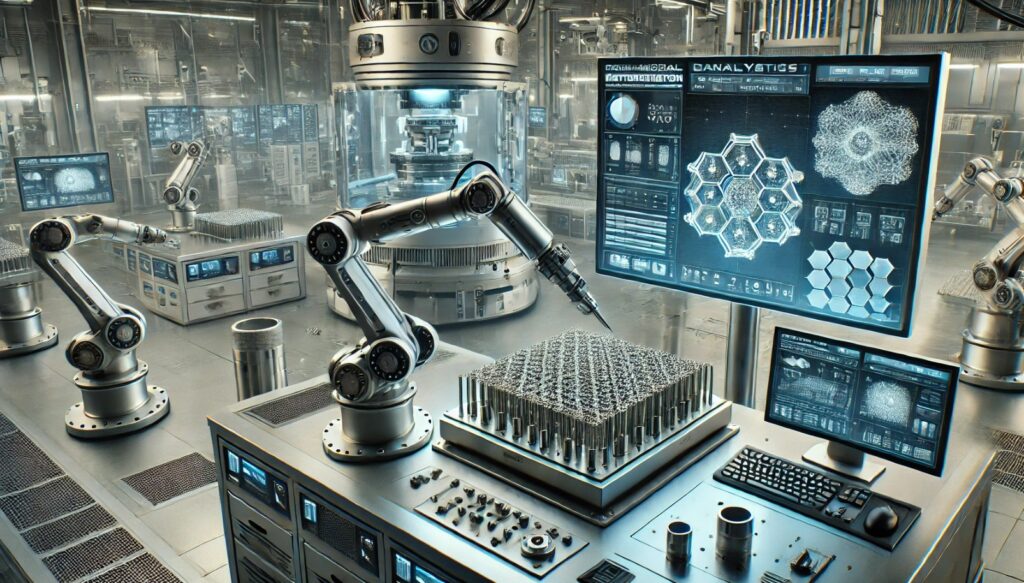

Next-Generation Materials Laboratory : Innovations in Alloys, Amorphous Materials, and Composites In the near future, materials laboratory is expected to feature robotic arms meticulously assembling samples, while AI systems simultaneously analyze data in real-time. Such a scene is not merely science fiction; it represents the forthcoming reality of next-generation labs that will revolutionize the way materials—from advanced alloys to sophisticated composite materials—are produced. Approximately a decade ago, the U.S. Materials Genome Initiative challenged scientists to discover and manufacture novel materials twice as fast and at a fraction of the traditional costs. Achieving these ambitious goals has become even more urgent due to climate change, geopolitical tensions, and unstable supply chains. To realize such accelerated innovations, a paradigm shift in materials laboratory workflow is essential. Future labs will replace slow, isolated experiments with fully integrated, automated pipelines that seamlessly combine design, synthesis, processing, and characterization. Utilizing next-generation experimental tools, automation, AI and machine learning integration, and multimodal characterization, these labs aim to quickly bridge the gap from material invention to practical production technologies. These advancements address critical bottlenecks in the manufacturing of metal alloys, amorphous materials (such as glasses), and composites, significantly impacting future manufacturing strategies. Key Innovations Enabling Future Materials