Advancing Dry Electrode Fabrication through Particle Interaction Engineering

Redefining Battery Manufacturing with Dry Electrode Fabrication

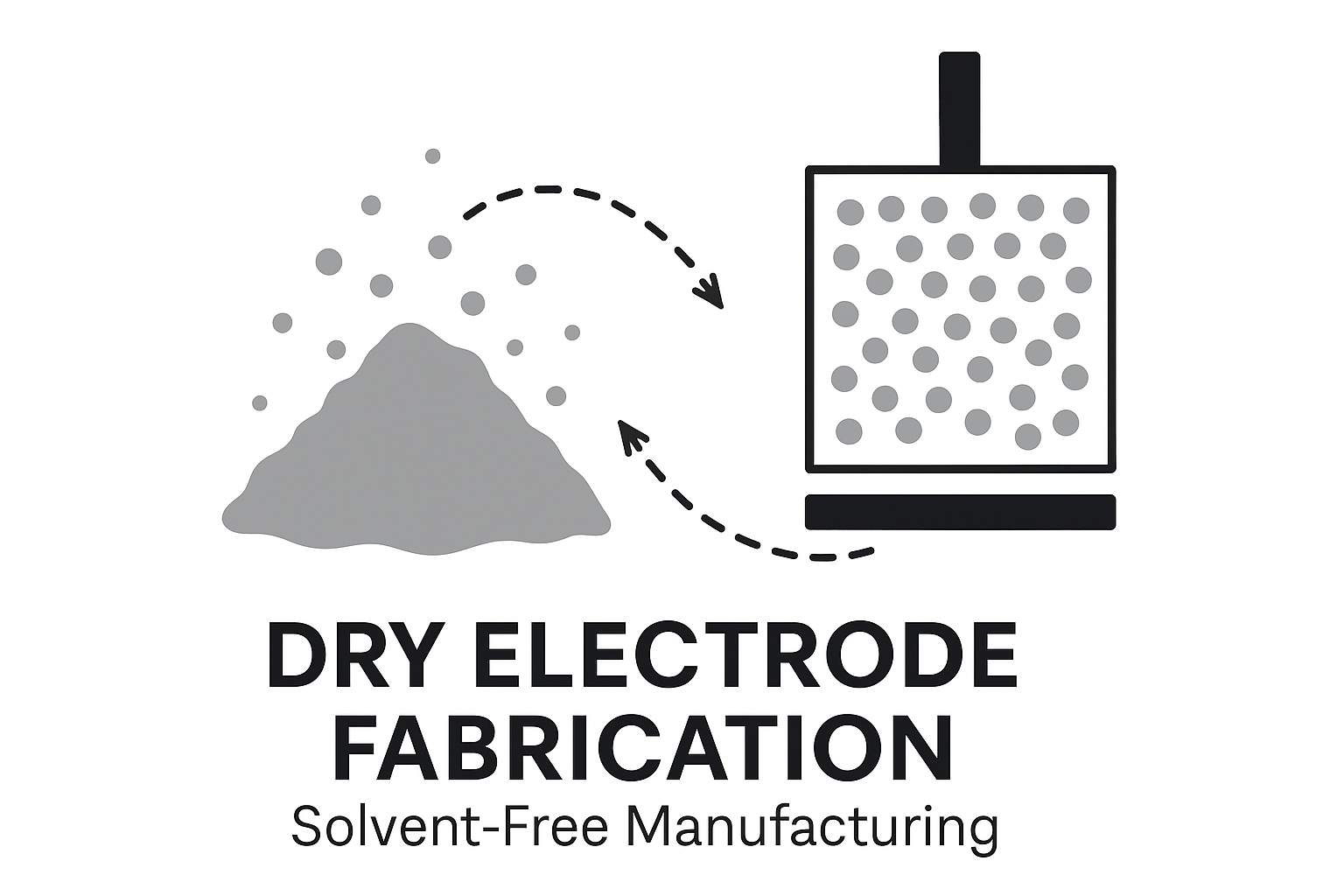

In recent years, the demand for high energy density lithium-ion batteries has surged due to their vital role in electric vehicles, portable electronics, and grid storage systems. However, the conventional wet electrode fabrication method—relying on toxic solvents like N-Methyl-2-pyrrolidone (NMP) and time-consuming drying steps—poses environmental, economic, and scale-up challenges. Dry electrode fabrication has emerged as a game-changing alternative, eliminating the need for solvents and enabling a more sustainable and cost-effective production line. Central to the success of this solvent-free approach is the control of particle interactions during the powder mixing process, which critically determines the final electrode quality.

Particle-Level Obstacles in a Solvent-Free Environment

One of the most significant challenges in dry electrode fabrication lies in ensuring a homogenous distribution of active material, conductive additives, and binders without the aid of a solvent. In traditional slurry-based systems, the solvent facilitates dispersion and coating of each component. In contrast, dry mixing depends entirely on the physical and interfacial interactions of powders, making it prone to issues such as agglomeration, poor adhesion, and phase separation. The cohesive nature of fine powders, especially carbon black and polymer binders like PVdF, often leads to clumping and uneven spatial distribution, which degrades electrode conductivity and mechanical integrity.

Designing the Mixing Protocol for Uniformity and Performance

To address these challenges, researchers developed two distinct mixing protocols for dry electrode fabrication: an all-in-one mixing strategy and a sequential, binder-precoating approach. In the all-in-one method, the active material (such as NMC622), conductive additive (carbon black), and binder (PVdF) are simultaneously mixed using a high-energy mixer. The sequential method, on the other hand, first coats the binder onto the active particles, followed by the addition of the conductive phase. Both approaches aim to achieve optimized particle adhesion, uniform binder distribution, and effective electronic conduction pathways.

The mixing quality was evaluated through a combination of dynamic angle of repose measurements to assess flowability, scanning electron microscopy (SEM) for morphological observation, and electrochemical impedance spectroscopy (EIS) to determine internal resistance. In addition, electrical conductivity and mechanical compressibility were tested to understand the interplay between microstructure and macro-scale properties.

Interactions That Drive Electrode Quality

Experimental results revealed that the all-in-one mixing strategy facilitated a more even dispersion of the conductive additive and binder, resulting in significantly improved powder flowability and reduced angle of repose. This enhanced uniformity contributed to the formation of a percolated conductive network, leading to superior electronic conductivity and reduced interfacial resistance in the fabricated electrodes. The resulting dry electrodes demonstrated stable mechanical compaction and sufficient adhesion strength, indicating their robustness during cell assembly.

In contrast, the sequential binder precoating method improved the adhesion of the binder to the active material, thereby increasing the mechanical integrity of the electrode layer. However, it compromised the homogeneous distribution of the conductive additive, leading to higher resistance and a decline in electrical performance. These trade-offs underscore the complexity of optimizing dry electrode fabrication, where micro-level interaction management significantly influences macro-level properties.

Bridging Performance and Manufacturability

Based on the experimental findings, it was evident that the all-in-one mixing approach holds a promising balance between electrical performance and mechanical reliability. By adjusting mixing energy, duration, and sequence, the dry electrode fabrication process can be tuned to deliver superior consistency across large-scale manufacturing lines. Furthermore, the elimination of drying ovens and solvent recovery systems reduces operational costs and environmental impact, positioning dry electrode fabrication as a viable, scalable, and eco-conscious solution.

To ensure reproducibility and scalability, additional focus was placed on the control of powder particle size distribution, surface energy tuning, and the use of surface-functionalized binders. These enhancements further minimize agglomeration and enable higher powder packing densities, contributing to improved areal capacity and better electrochemical stability in high-loading configurations.

Toward Commercial Scale Adoption

The success of this study not only highlights the technical feasibility of dry electrode fabrication but also opens up new pathways for its broader application across various battery chemistries. With further development, dry mixing protocols can be adapted for other active materials such as LFP, NCA, or solid-state electrolyte systems. The use of advanced process analytical technologies (PAT) and in-line monitoring tools will enable real-time quality assurance, making it easier to integrate dry electrode fabrication into gigafactory-scale production lines.

In addition, dry electrode fabrication holds particular promise for the production of next-generation high-energy and solid-state batteries where moisture sensitivity and solvent compatibility are critical concerns. The ability to eliminate solvent use entirely supports compliance with increasingly strict environmental regulations and lowers total cost of ownership over the battery lifecycle.

Engineering the Future with Dry Electrode Fabrication

Dry electrode fabrication is no longer a theoretical concept but a technically validated and industrially viable approach that redefines the standards of lithium-ion battery production. Through a deep understanding of powder-particle interactions and strategic mixing protocol design, researchers have demonstrated that dry processing can achieve high-performance electrodes without compromising manufacturability. With further optimization and investment, dry electrode fabrication is set to become a cornerstone of sustainable battery manufacturing, fulfilling the urgent demand for cleaner, faster, and more efficient energy storage solutions.

Source: https://thebulklab.com