Meet Superwood : The Wood That’s Stronger Than Steel

Scientists have discovered how to transform ordinary wood into “Superwood” – an ultra-strong, lightweight material that could replace steel and aluminum in everything from buildings to nails. For centuries, wood has been a trusty building material, prized for its warmth, flexibility, and renewability. But even the sturdiest oak or bamboo has its limits. A wooden beam can only carry so much weight before it cracks, and we rely on steel nails and girders when sheer strength is needed. In a lab in Nanjing, China, researchers dipped a block of wood into a special chemical bath and pulled out something astonishing: a block of wood now as hard as metal.

This Superwood is not only stronger than ordinary wood – it can even rival metal in strength. In one test, a nail made of this treated wood outperformed a steel nail, holding firm where the metal nail gave way. Using a blend of clever chemistry and nature’s design, the researchers have opened the door to a future where wood might replace metal in many places – from nails and beams to entire buildings – all while remaining lighter and more sustainable.

The Discovery of Superwood

It began with a simple question: how can wood be made as strong as metal? Wood is composed of straw-like hollow fibers (cellulose) glued together by lignin; those empty pockets keep it light but also limit its strength. For years, scientists have tried to strengthen wood by compressing it or infusing it with polymers. Some success stories emerged (densified wood harder than regular lumber), but those methods required heavy presses, high heat, or chemical additives that made the wood less green.

At Nanjing University, researchers wondered if there was a smarter way. Instead of crushing wood with brute force, they turned to nature. When wood dries, it shrinks – so what if they could make it shrink just right, compacting itself from the inside out? After some trial and error, the team found a treatment that did exactly this. The treated wood was incredibly strong – in lab tests it surpassed ordinary wood by a wide margin and even matched or beat some aluminum alloys in strength. Their once ordinary wood had transformed into Superwood.

The Development History

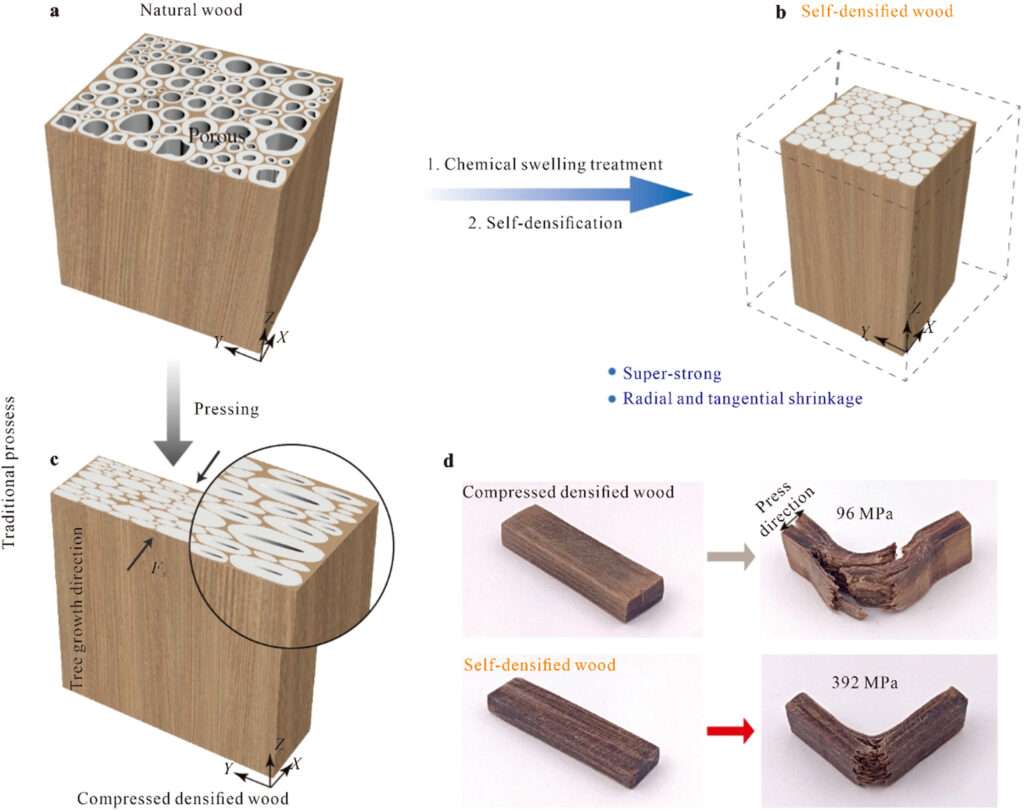

For decades, scientists have explored ways to make wood stronger. One recent approach is densification – squeezing out wood’s internal voids to make it harder. One such method involved boiling wood in chemicals then hot-pressing it flat. It did make wood stronger, but only by compressing the material in one direction, and it required lots of energy and chemicals. The Nanjing team sought a more uniform and eco-friendly solution. After many trials, they discovered that by removing some lignin and then swelling the wood, the wood could collapse inward uniformly. This breakthrough produced wood about eight times stronger in bending than before, without any glue or heavy machinery.

The Production Method: How to Make Superwood

Making Superwood involves three main steps:

- Partial “De-gluing” (Delignification) – The process begins by boiling the wood in a mild chemical bath (like those used in papermaking). This removes part of the lignin – the natural “glue” in wood that holds fibers in place. With some of that glue gone, the fiber bundles loosen up and can move closer together.

- Fiber Swelling – Next, the porous wood is soaked in a heated organic solvent containing a special salt. This causes the cellulose fibers to swell up, a bit like a sponge soaking in water. The fibers expand inward into the empty pores, filling in the wood’s hollow spaces.

- Air-Drying Compression – Finally, the treated wood is taken out and simply left to air-dry at room temperature. As it dries, it shrinks uniformly inward from all sides, like a sweater tightening up after washing. Because the wood’s length doesn’t shrink (the fibers stay long and aligned), the shrinkage happens only in width and thickness, pulling everything tightly together. In essence, the wood compresses itself without any external press. The end result is a smaller, much denser piece of wood – our Superwood.

Not only is Superwood extremely strong, but making it is also energy-efficient. Unlike older methods, no high-pressure presses or extreme heat are required – the wood essentially does the work itself as it dries. And because the process keeps the wood all-natural (no heavy resin added), the material stays lightweight. In fact, pound for pound this densified wood has a higher strength-to-weight ratio than many metals.

Current Applications and Future Potential

To show what Superwood can do, the researchers fashioned a nail from a sliver of Superwood. They hammered this wooden nail through three layers of regular wood with ease. In load tests it withstood over 300 newtons (about 30 kg of force) before the wooden board cracked – and the Superwood nail stayed intact, outperforming a steel nail. Nails made of Superwood could one day be used in building construction, reducing the need for metal fasteners.

Beyond nails, this new material could let us reimagine bigger projects. Architects are already eyeing this new wood to replace some steel beams in buildings – perhaps one day even using wooden pillars in skyscrapers to carry loads once reserved for steel. And since it won’t rust and can be treated to resist rot, Superwood could work well in bridges or other outdoor structures too.

Even car manufacturers might use it – a Superwood car frame would be far lighter than steel, boosting fuel efficiency, and it’s made from renewable wood instead of mined metal. Moreover, Superwood comes from a renewable resource and doesn’t require the high-energy processing that metals do, so its carbon footprint is much lower. In short, this super-strong wood could be a sustainable alternative to steel.

Superwood is still new from the lab, and it may be a while before it hits hardware stores. Researchers need to test its long-term durability, scale up production to larger pieces, and ensure it’s cost-effective to produce. But the breakthrough is real. A piece of wood, treated just right, can get a ten-fold boost in strength and stand toe-to-toe with metal. It’s a reminder that with science, even an old material like wood can learn new tricks. Superwood could one day transform construction, helping build a stronger, greener world – one wooden plank at a time.

Paper: Huang, Dafang, et al. “Self-densified super-strong wood.” Journal of Bioresources and Bioproducts 10.2 (2025): 199-208.

https://doi.org/10.1016/j.jobab.2025.03.001

Source: https://thebulklab.com